S/V Vive Grande

/Name: Vive Grande (original name Sunglow)

Builder: Fritz Dionne and Alois Bauer in Pico Rivera, CA

Design/ material: Samson C- Breeze/ Ferro-Cement Hull

Launched: 1981, USCG Documented # 1224940, Long Beach CA.

Sail Plan: Staysail Ketch, 1,155 sq ft

LOA 52’10”

LWL 38’4”

Draft 7’ 4”

Beam 13’

Main Mast: 58’

Displacement 32 ½ tons (68,000 lbs.)

Vive Grande is a 53’ Ultra Lounge Ketch Sailboat Custom built by Fritz Dionne and Alois Bauer in the front yard of Fritz’s Pico Rivera (California) home. They began construction of the vessel in 1969 but she was not launched until 1981. She is a ‘C- Breeze’ ferro- cement hull built to specifications by Samson Marine. Ferro-cement boats are built using a mixture of cement and sand over a steel matrix frame. The method is well over 200 years old and is widely used in Europe, New Zealand, and Australia but many fine craft have been made in the USA.[i] Although simple in principle, the construction is very labor intensive and has a controversial history in the United States. Vive Grande is 52’10” overall with a beam of 13’. Weighing over 30 tons she has a full-keel draft of 7 ¼ feet and a rudder as big as a barn door.

Vive Grande is unique in her large flat deck and open space up top. Designed for steady long-range sailing she loves wind in the 15-20 kt. range and stays dry on deck even with significant wind waves. The Ketch sail plan allows for easy handling with just two crew and easy balancing so she steers herself upwind with no rudder input. The heavy displacement of the boat makes for a steady ride as she cuts through the wind and waves.

Accommodations

Down the companionway hatch she has a large and bright main salon and a spacious galley. She boasts 3 private staterooms and two heads (toilets) and a full-sized shower. Interior spaces are large compared to similar sized boats and brilliant utilization of space allows for plenty of stowage for long voyages. She has wonderful creature comforts including hot water, refrigeration, 4 burner stove with oven, TV and DVD player, wireless internet, stereo and good batteries, plus an inverter and generator for offshore electrical needs.

On deck she is equally spacious with a wonderful shaded center cockpit. The deck has ample storage for Kayaks, SUPs, surf boards, Scuba/ Snorkel Gear, rafts, ect.

Construction

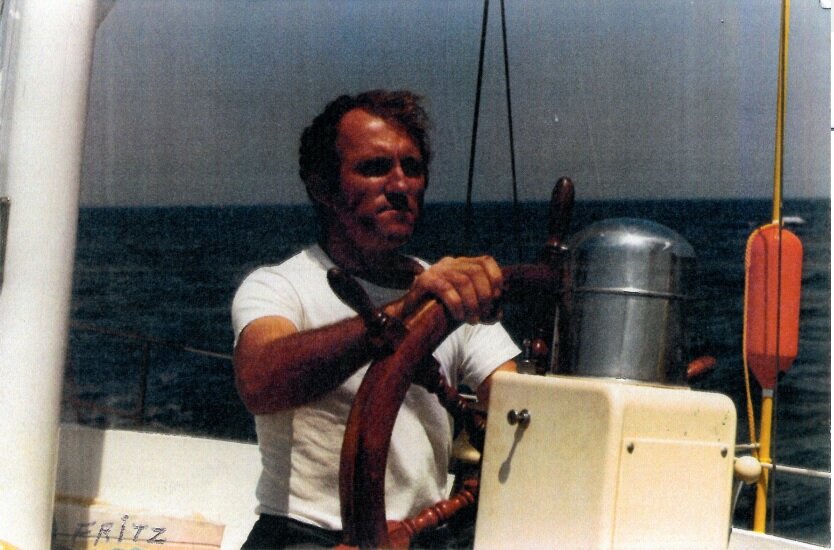

Fritz Dionne was born in Canada and gained boatbuilding experience in his early teenage years building wooden minesweepers for the war effort. He came to the US at age 27 because he had, “always wanted to live in California.” He became a finish carpenter by trade where he gained a lifetime of experience and respect for wood as a building material and a way of life. Fritz loved sailing and wanted to build his own sailboat of about 35’ out of Alaskan Cedar. He said this wood was an excellent boat building material because worms and insects do not like it and it does not rot. He started to acquire some good boatbuilding planks but soon he became concerned. All the trees in the Pacific Northwest had been overharvested so much that there were hardly any trees left big enough to make a decent boatbuilding planks.

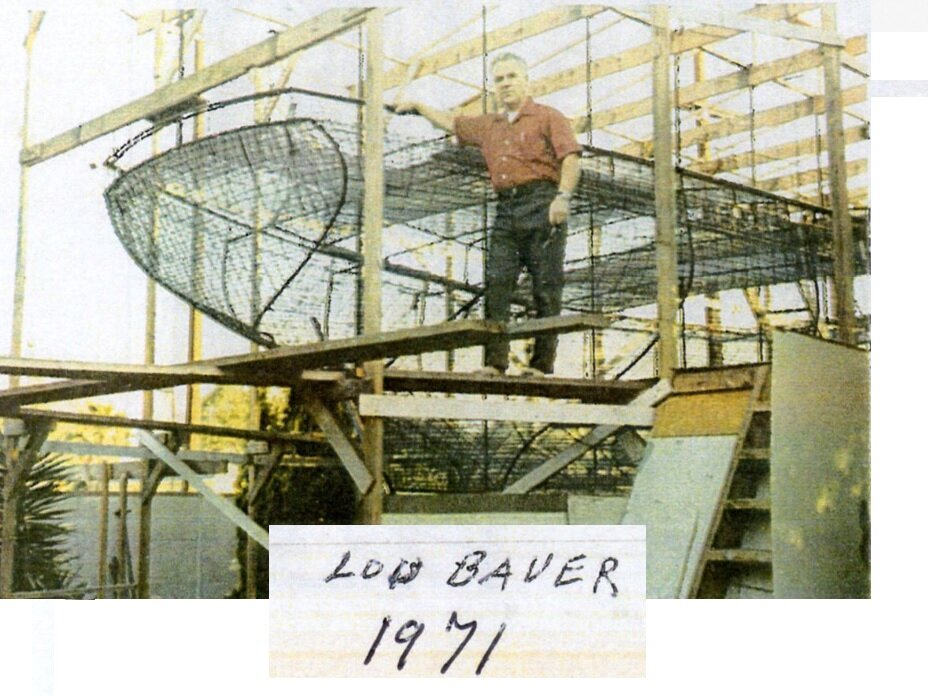

Alois (Lou) and Ruth Bauer (his wife) were good friends with Fritz and his wife and they also enjoyed sailing. Lou and Ruth were able to travel for free because Ruth worked for American Airlines. The couple Traveled to Australia where ferro-cement construction was more common and thought, “why don’t you build it out of Cement?” They visited shipyards in Australia to learn more about the process.

The two couples decided to pool their money together ($8,000 each) to build a bigger boat using a design by Canadian company “Samson Marine.” John Samson (founder) was a tried and true sailor from Canada who provided DIY plans for all types of craft. Samson encouraged countless numbers to throw off the shackles of working life, build a boat and sail off to the South Pacific.[ii] They decided to build the boat in Fritz’s front yard on Sunglow Street.

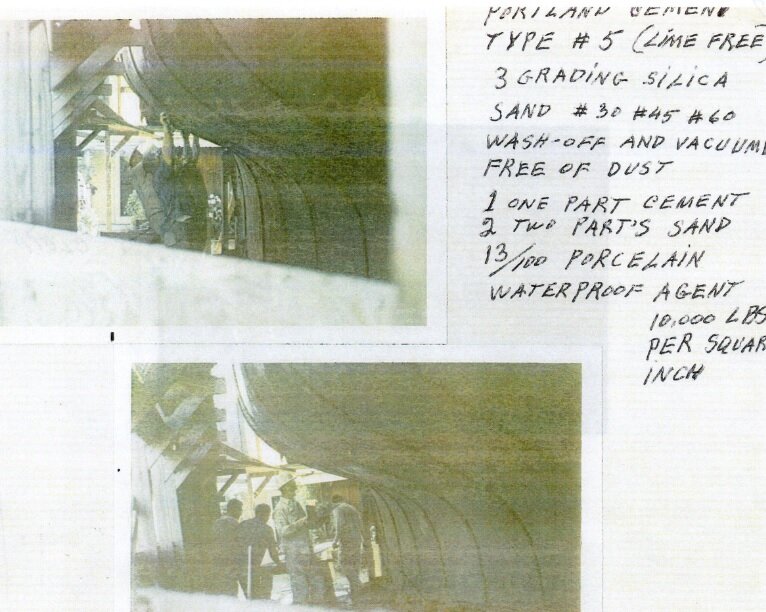

They were beginning to gather the materials when something else came up. They met a man from Germany who was a concrete engineer in commercial building. He had also gained a lot of experience in ferro-cement construction after the German government commissioned him to build a fleet of 600-700 fishing boats. He helped Fritz and Lou with all the cement dealings and on plastering day

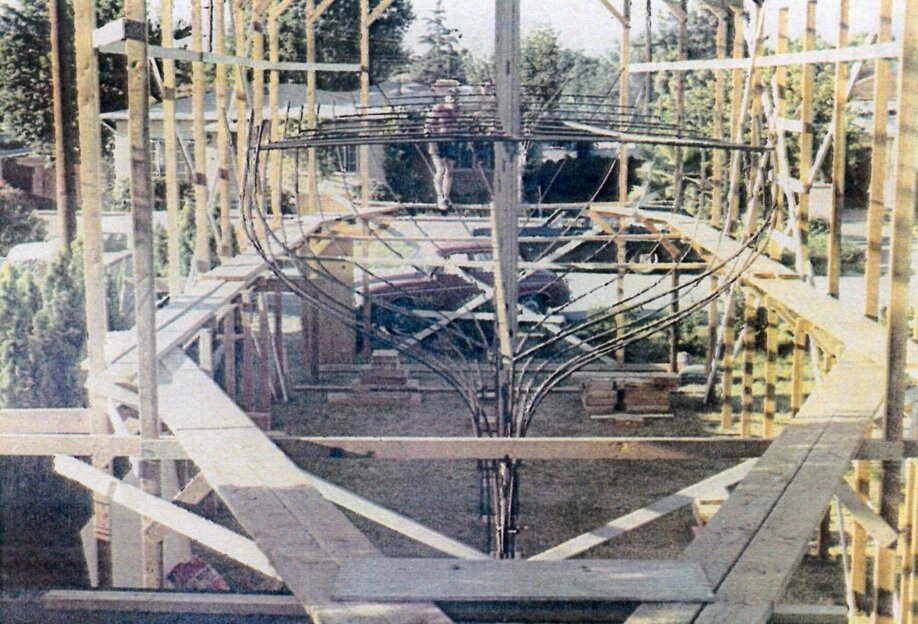

The first step in building was to erect a large wooden structure that would support the metal armature. Lou went around to the neighbors to ask if they would mind a large boat being built in the front yard on their street and they all said the same thing “I don’t care as long as you don’t build it in my yard!” At about this point the planning dept of Pico Rivera stopped by the house and gave a notice to “stop all construction.” The inspector thought that they were trying to build a “permanent structure” with no foundation. Fritz explained that they were building a boat and not a structure that was the end of the city’s interest.

Although it was not permanent, the construction and waiting period to get a marina slip had the boat sit in the yard for over 10 years.

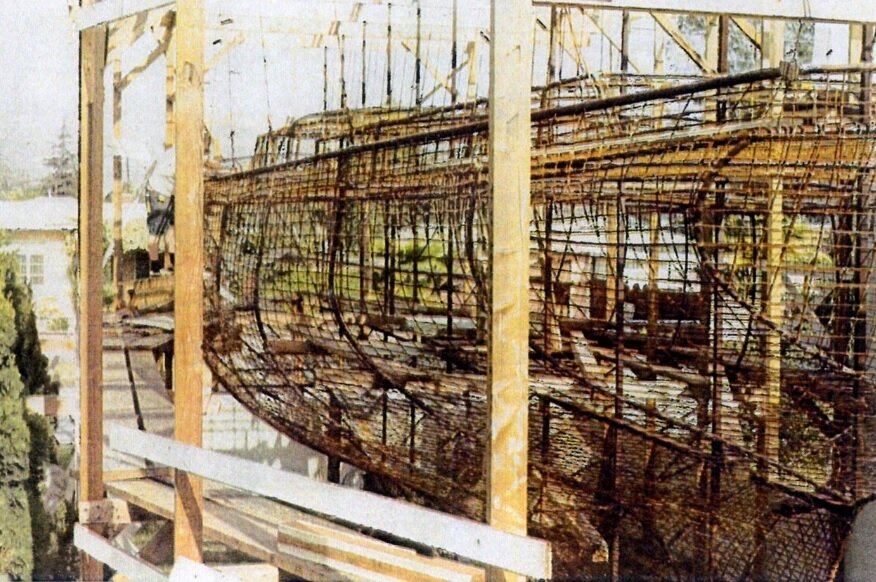

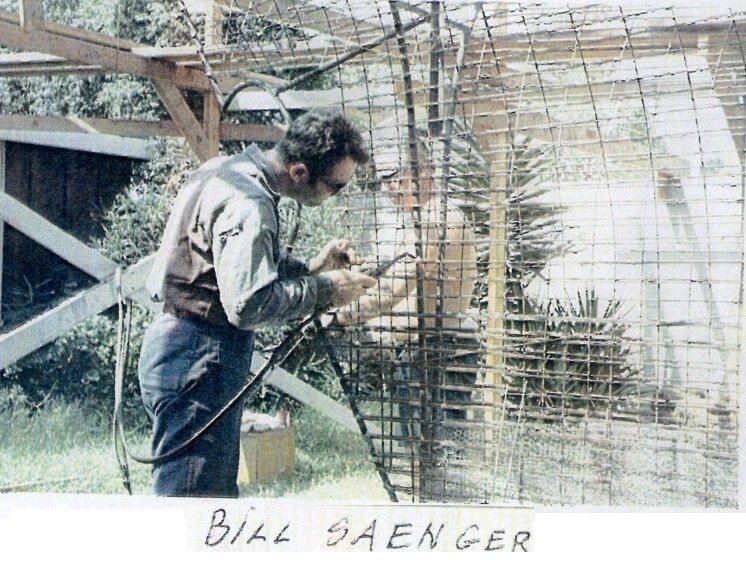

The sheer (general shape and deck edge) was formed using galvanized pipe. High tensile steel rod was used for the diagonal stringers and rods. Then 4 layers of galvanized mesh was added inside and 4 layers of mesh outside of the matrix. Some welding was done on the frame, but most of the steel matrix was wire tied together with over 100,000 wire ties. [iii] Helping with the minimal welding was boilermaker, Bill Saenger(Pictured). Bill worked in the space division and made titanium fuel (and other) tanks for the Apollo Missions, but Fritz said he got tremendous enjoyment by helping with this unique and challenging project.

Plastering day is the most important day of construction and 15 guys were utilized working from sun-up until 2 am to make sure everything went smooth. They started from the inside out and the top down to ensure that as the steel armature sagged with the added weight of the cement, the shape would not be significantly altered potentially creating voids in the plaster (air pockets). Cement was Type V Lime Free and silica sand was carefully washed and sieved for sizes # 60, #45, #30 and blended with 13% Porcelain for waterproofing. Cement, water and Porcelain were mixed first to keep close track of mixture. After the plastering was complete, they sewed together burlap to wrap the whole boat in order to keep the cement continuously wet. This controls curing of the cement, adding strength and minimizing cracking. After 32 days of wet curing she was tested at 10,000 PSI breaking strength. Lou thought he would conduct his own test so he shot the boat with a .38 cal pistol although Fritz asked him not to do it in town. The bullet bounced off with the boat barley even nicked.

One of Fritz’s good friends, Wady Larson helped with the plastering and had built his own C-Breeze Ketch virtually identical to Sunglow. Wady lived on his boat and did a three-year circumnavigation leaving Southern California and thru the south pacific. He and his crew experienced a severe hurricane near Hawaii when the eye of a hurricane went right over them and in the middle of the storm they were completely be-calmed for several hours. During this storm his boat suffered a complete knockdown where the mast hit the water. He said that after the 53’ yacht had virtually been turned upside down, she came back up slow and steady and was shaken up, water was everywhere but basically unphased.

Fritz and Lou were part of “The California Ferro Cement Boat Building Club” where builders shared experiences and tips. Over 450 boats were built in California and most never went in the water. According to Fritz it was just too much work for many people and a lot of boats were abandoned due to using the wrong steel, the cement being put on too thick, some ran out of money, oftentimes they just had bad information. These things put a lot of strain on marriages and partnerships. Fritz said, “my wife put up with it, but she was pretty easy going and loved sailing!” He admits they got lucky with all the good information they were able to obtain and the helpful hands. Especially considering the large number of cement boats poorly built all over the world.

The hull was completed in 1976 but because there were no slips available, she would not be launched (in Long Beach, CA) until 1981. They never did realize their prospects of sailing off to the Marquesas Islands. “It is a dream,” says Fritz “a dream for younger people and you never know what life will bring you. We never had any savings, nothing to come back to and life got in the way.”

The boat was donated to “Access to Sailing” to promote sailing for veterans through the Long Beach veteran’s association, before coming under private ownership and private charter in 2010.

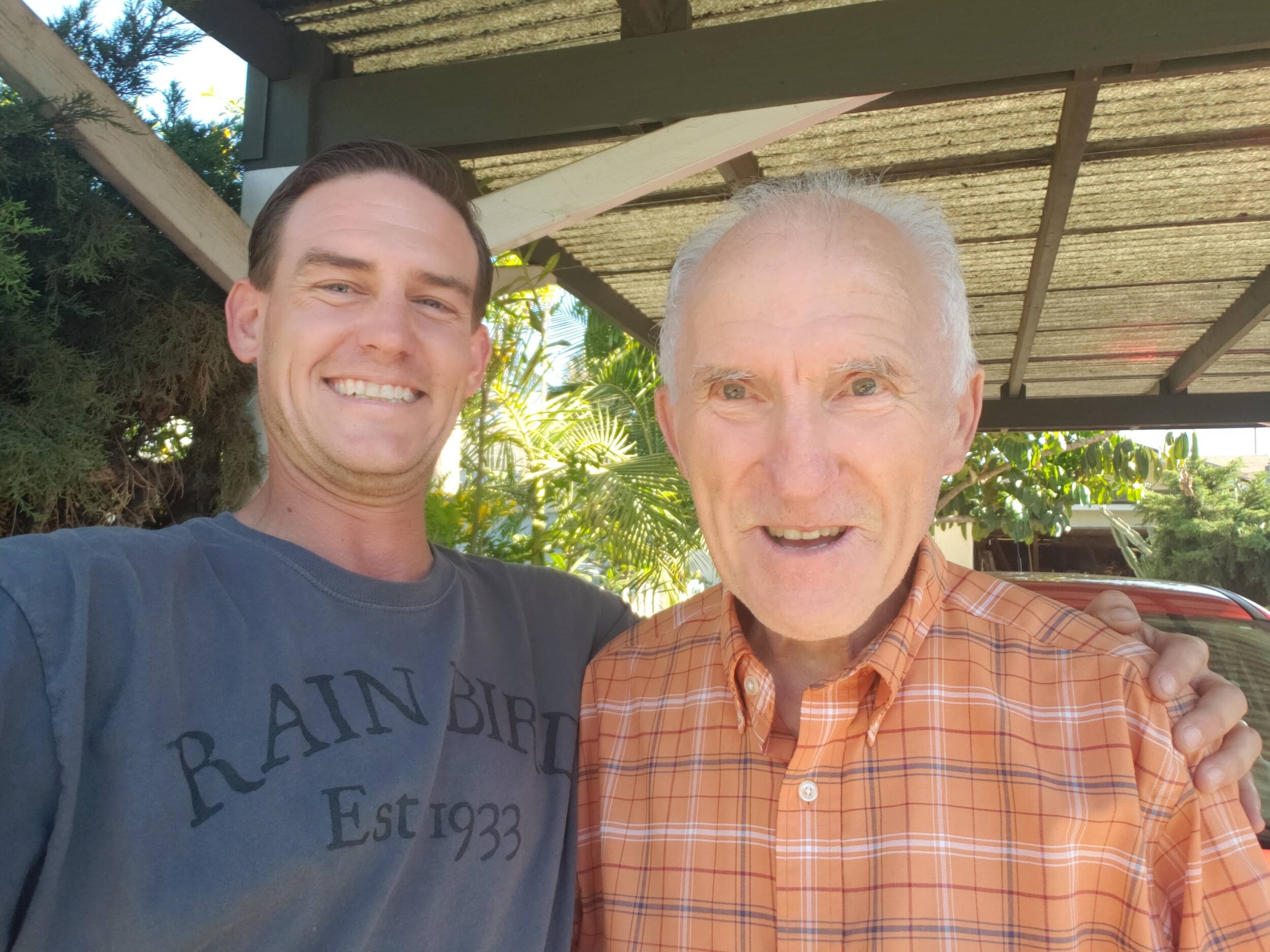

Lou Bauer died in 2005 of Cancer, soon after his wife Ruth. Mrs. Fritz Dionne has also passed on. At the time of writing, Fritz is still alive and well and continues to contribute his amazing craftsmanship and stories about his old boat. He still loves to sail with the new owners when he is not traveling the world via cruise ship. He is a proud donor to various charities that help protect those big beautiful forests that gave him his livelihood.

He says that like many of his projects throughout his life, he is happy to know that countless people have shared the love of sailing and will continue to enjoy his works of fine craftsmanship for many years to come.

References

[i] Colin Brookes, Ferro- Cement Boats, 2008. Hartley & Brookes Associates, www.ferroboats.com

[ii] John Samson A New Way of Life, 1970, Mitchell Books Limited, Vancouver B.C.

[iii] Colin Brookes, Ferro- Cement Boats 2008 . Hartley & Brookes Associates , www.ferroboats.com

*Photos and Interview from “Fritz Dionne” at his Pico Rivera Residence on June 16th, 2015